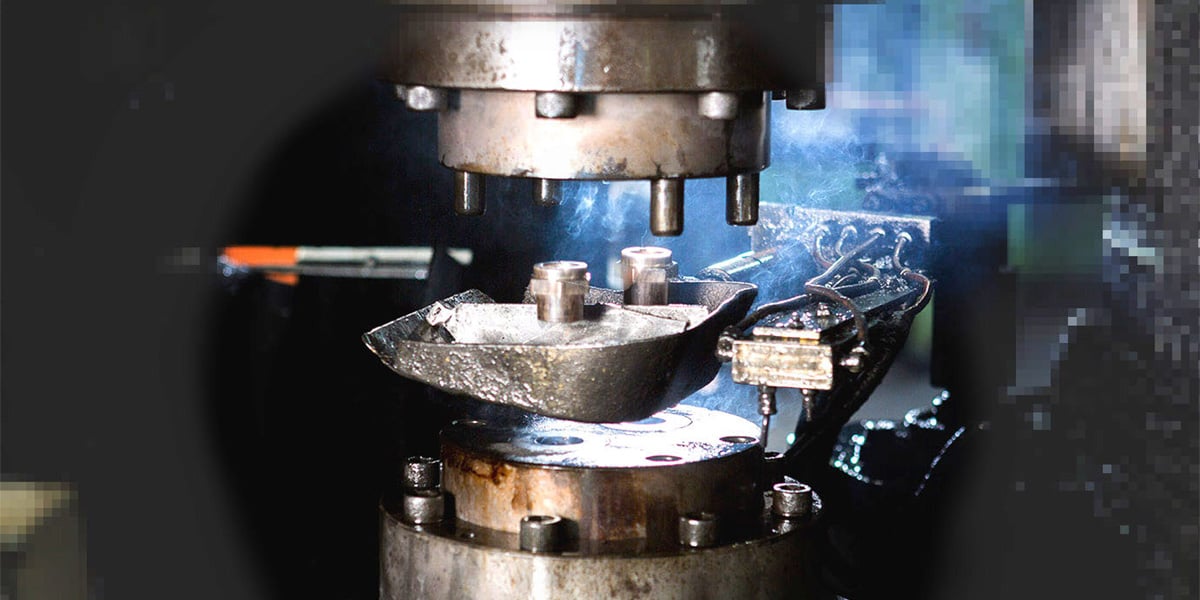

The die-cast

Also known as Shell Foundry under pressure.

Particular permanent foundry process, where molten metal (aluminum alloys or zamak) is injected at high pressure into a metal mold. A process suitable for serial production that guarantees a raw product ready for aesthetic polishing.

Global Partner

A single point of contact. A precise order manager able to meet your mechanical and aesthetic requirements.

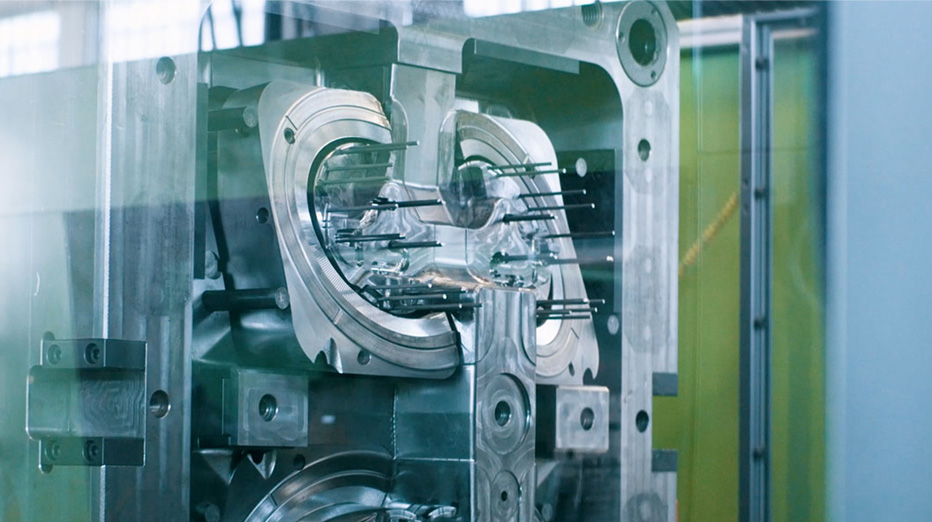

Let's start with the Mold.

To obtain high-quality polished, galvanized or painted products, it is necessary to start from the study of the construction of the mold with the relative injections and outbursts of material. Die-casting, of a part that will have to be polished, has process and production dynamics that are very different from the die-casting of parts without this aesthetic purpose, so that during the polishing phase no defects emerge on the surface of the piece.

In collaboration.

We rely on the most important Italian die-casting companies, with whom we collaborate; from the choice of the alloy to be used to the shared study of the mold and mold flow. Always having clear aesthetic expectations and the processes to which the product will then be subjected.